Plastic Injection Molding Machine Market Growth Analysis Research Report by Raw Material (Polypropylene, Acrylonitrile Butadiene Styrene (ABS), Polystyrene, Polyethylene, Polyvinyl Chloride (PVC), Polycarbonate, Polyamide, Acrylonitrile, Butadiene, Styrene, High Density Polyethylene, Other Raw Materials), By Application- Global Forecast to 2034

Jan-2026 Formats | PDF | Category: Manufacturing & Construction | Delivery: 24 to 72 Hours

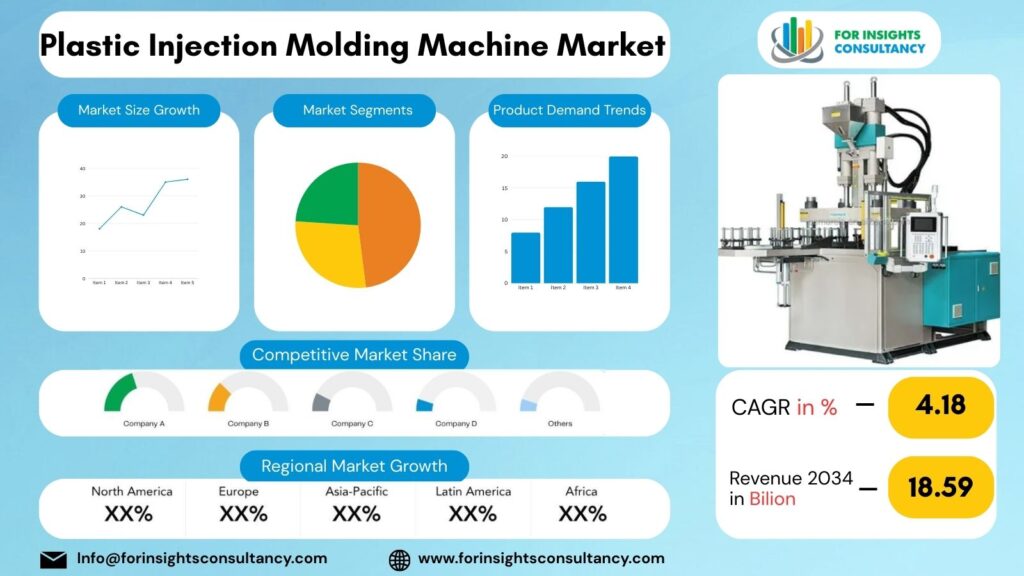

The Global Plastic Injection Molding Machine Market is estimated to be valued at USD 13.19 Billion in 2025 and is expected to reach USD 18.59 by 2034, growing at a compound annual growth rate (CAGR) of 4.18% from 2026 to 2034.

Plastic Injection Molding Machine Market: Overview and Growth in the Upcoming Year

The Plastic Injection Molding Machine Market is set to grow steadily in 2026, you know, thanks to rising industrial production and a broader slate of applications across automotive, packaging, electronics, healthcare, and consumer goods. Plastic injection molding machines are the workhorses for making high-precision plastic components in really large volumes, basically essential for mass production. One big driver? the automotive sector’s continued shift toward lightweight plastic components to improve fuel efficiency and back electric-vehicle production. And the packaging boom—especially flexible and rigid plastic packaging—keeps fueling strong demand for advanced molding equipment. The electronics and medical device sectors are also contributing a lot, since they require highly precise and energy-efficient machines for producing intricate plastic parts.

Tech advances are playing a huge role here. In 2026, manufacturers are increasingly jumping onto electric and hybrid injection molding machines because they’re more energy-efficient, give you precise control, and need less maintenance than traditional hydraulic systems. And with automation, robotics, IoT connectivity, and smart monitoring systems getting integrated, production efficiency goes up and downtime goes down—totally in line with Industry 4.0 trends.

Regionally, Asia-Pacific is still on track to hold its dominant position in 2026, you know, powered by solid manufacturing activity in China, India, Japan, and South Korea. North America and Europe are growing steadily too—driven by tech upgrades, reshoring of manufacturing activities, and a bigger push toward sustainable production practices.

All in all, the Plastic Injection Molding Machine Market in 2026 looks like stable, technology-driven growth, with sustainability, automation, and energy efficiency emerging as the big themes guiding where money gets invested and how companies compete.

Top Companies Covered In This Report

- Arburg GmbH + Co KG

- HAITIAN INTERNATIONAL

- KraussMaffei

- Milacron

- NISSEI PLASTIC INDUSTRIAL CO., LTD.

- ENGEL AUSTRIA GmbH

- Chen Hsong Holdings Limited

- UBE Machinery Inc.

- Husky Technologies

- WITTMANN Technology GmbH

- Sumitomo (SHI) Demag

- JSW

- Toyo Machinery & Metal Co., Ltd.

- Battenfeld-Cincinnati

- Shibaura Machine

- Fu Chun Shin

- HPM North America Corporation

- Negri Bossi S.p.A.

- Borch Machinery Co., Ltd.

- Shuangsheng Injection Molding Machine

Plastic Injection Molding Machine Industry News

2025-08-06 Japan Steel Works launches 40,000 kN electric injection moulding machine

Japan Steel Works (JSW) has expanded its standard lineup with the introduction of the world’s first ultra-large all-electric injection moulding machine (e-IMM) featuring a clamping force of 4,000 metric tons (40,000 kN). This development responds to the growing global demand for lighter components, particularly in the automotive industry, where electric vehicles require lightweight exterior parts such as bumpers, tailgates, and battery cases made from plastic.

2026-02-11 Wittmann at Chinaplas 2026

At the Chinaplas 2026 trade fair in Shanghai, the Wittmann Group will present a broad portfolio of solutions for plastics processing, including injection molding machines, automation and auxiliary equipment. The key element of the exhibit will be the first all-electric EcoPrimus injection molding machine produced at the company’s plant in Kunshan, China.

Detailed Segmentation and Classification of the report (Market Size and Forecast – 2034, Y-o-Y growth rate, and CAGR):

Segment By Raw Material

- Polypropylene

- Acrylonitrile Butadiene Styrene (ABS)

- Polystyrene

- Polyethylene

- Polyvinyl Chloride (PVC)

- Polycarbonate

- Polyamide

- AcrylonitrileButadieneStyrene

- High Density Polyethylene

- Other Raw Materials

Segment by Application

- Packaging

- Building and Construction

- Consumer Goods

- Electronics

- Automotive and Transportation

- Healthcare

- Other Applications

Segment by Technology

- Hydraulic

- Electric

- Hybrid

Regional Deep-dive Analysis:

The report provides in-depth qualitative and quantitative data on the Plastic Injection Molding Machine Market for all of the regions and countries listed below:

North America

By 2026, the North America Plastic Injection Molding Machine market is still on a steady climb—not flashy, but steady—driven by strong demand across packaging, food & beverage, healthcare, and industrial apps. North America already holds a meaningful slice of the global market, about 20–23% of global revenue, with solid performance in both flexible and rigid film segments.

Growth here is fueled by a handful of factors: a mature packaging sector, a rapid rush of e-commerce, and rising appetite for advanced, sustainable film solutions for food, pharmaceutical, and consumer products. As online retail keeps growing, the need for protective packaging, poly mailers, and high-barrier films rises, boosting demand for plastic films and sheets. And companies in the region are plowing into innovation and R&D, chasing recyclable, multi-layer, and biodegradable film technologies to meet regulatory and consumer sustainability expectations.

Europe

By 2026, the Plastic Injection Molding Machine market in Europe isn’t about fireworks—it’s about steady, sustainable growth. Demand patterns are evolving, regulatory dynamics are shifting gears, and innovation in material tech is rolling on. Europe accounts for a solid chunk of the global market—roughly 20–22% of total consumption. That share makes sense: a strong manufacturing base, plus well-established packaging and industrial sectors.

European markets are being shaped by tight environmental rules and sustainability goals—it’s basically pushing more recyclable, mono-material, and biodegradable film solutions to the fore. Companies across Europe are doubling down on eco-friendly materials and construction types that line up with EU regulations aimed at cutting plastic waste and boosting the circular economy. That regulatory influence is a key growth factor in 2026, and, to be honest, it’s likely to shape product innovation and demand dynamics across the region.

Major economies—Germany, Italy, and France—are still the heavy hitters, with Germany often named as one of the largest national markets thanks to its strong industrial and packaging demand. Growth in these markets is being backed by investments in advanced film technologies, the adoption of high-barrier and multi-layer films that extend shelf life, and the increasing use of plastic sheets in construction and industrial applications.

Asia-Pacific

Asia-Pacific Plastic Injection Molding Machine market is set to stay the biggest and fastest-growing regional piece of the global puzzle in 2026, outpacing everyone else in both production and consumption. In 2025, the market was valued at around USD 61.6 billion, and even though not every report slips a clean standalone number for 2026, the vibe is clear: it’s forecast to grow at a solid mid-single-digit to high-single-digit CAGR through 2035 — driven by broad industrial expansion and rising material demand. By 2035, forecasts say the Asia-Pacific market could top USD 103.9 billion, signaling substantial continued growth from 2026 onward.

And it’s not just about packaging—industrial demand matters too, with construction materials, electronics, agriculture films, and pharmaceutical packaging pushing extra volume growth. China remains the largest national market in the region, backed by massive manufacturing capacity and a big domestic appetite, while India is among the fastest-growing markets thanks to accelerating industrial activity and rising domestic consumption.

So, in short: Asia-Pacific’s 2026 Plastic Injection Molding Machine market is all about scale and accelerating demand, underpinned by solid regional consumption in packaging and industrial applications, steady manufacturing growth, and a rising focus on sustainable materials — making it a core engine of the global industry’s growth trajectory.

Middle East and Africa

In 2026, the Plastic Injection Molding Machine market in the Middle East and Africa (MEA) region is set to keep growing, a steady, not-too-exciting kind of growth—it’s being underpinned by expanding packaging demand, industrial development, and a shift toward sustainability. While there aren’t a ton of standalone 2026 numbers specifically for “films & sheets,” plenty of industry analyses point to broader momentum across related segments like plastic packaging films and flexible packaging in MEA.

The plastic packaging films segment — which basically overlaps with the plastic films portion of the plastics films & sheets market — is projected to grow steadily in the coming years. Forecasts for MEA say the plastic packaging films market will expand in both volume and value through the latter half of the decade, driven by increasing consumption in food & beverage packaging, pharmaceuticals, personal care goods, and logistics wraps. Flexible films, pouches and wraps are among the fastest-growing product forms because e-commerce keeps climbing and there’s more demand for shelf-stable packaging formats. Flexible formats, including films and wraps, are expected to keep expanding as brand owners chase lightweight and efficient packaging solutions.

All told, the MEA Plastic Injection Molding Machine market in 2026 is characterized by moderate yet steady growth, shaped by rising packaging demand, industrialization, regional production investments, and a bigger focus on sustainability—though growth rates may stay below those seen in Asia-Pacific or North America.

Frequently Asked Questions with Answers

What is the Plastic Injection Molding Machine market size and growth forecast?

Plastic Injection Molding Machine Market is projected to reach a value of USD 13.19 Billion in 2025 and is anticipated to grow to approximately USD 18.59 billion by 2034. This expansion reflects a compound annual growth rate (CAGR) of 4.18% during the forecast period from 2026 to 2034.

Who are the key players in the Plastic Injection Molding Machine market?

The Plastic Injection Molding Machine Market Includes Major Companies Arburg GmbH + Co KG, HAITIAN INTERNATIONAL, KraussMaffei, Milacron, NISSEI PLASTIC INDUSTRIAL CO., LTD., ENGEL AUSTRIA GmbH, Chen Hsong Holdings Limited, UBE Machinery Inc., Husky Technologies, WITTMANN Technology GmbH, Sumitomo (SHI) Demag, JSW, Toyo Machinery & Metal Co., Ltd., Battenfeld-Cincinnati, Shibaura Machine, Fu Chun Shin, HPM North America Corporation, Negri Bossi S.p.A., Borch Machinery Co., Ltd., Shuangsheng Injection Molding Machine, Others.

What are the current and future trends for Plastic Injection Molding Machine market?

Rising adoption of electric and hybrid injection molding machines due to energy efficiency and precision. Increased integration of automation, robotics, and Industry 4.0 connectivity for smart manufacturing.

Which regions dominate the Plastic Injection Molding Machine market?

The Asia-Pacific region dominates the Plastic Injection Molding Machine market, followed by North America and Europe due to strong manufacturing and automotive industries.

Key insights provided by the report that could help you take critical strategic decisions?

- Regional reports analyse product/service consumption and market factors in each region.

- Reports highlight possibilities and dangers for suppliers in the Plastic Injection Molding Machine Market business globally.

- The report identifies regions and sectors with the highest growth potential.

- It provides a competitive market ranking of major companies, as well as information on new product launches, partnerships, business expansions, and acquisitions.

- The report includes a comprehensive corporate profile with company overviews, insights, product benchmarks, and SWOT analysis for key market participants.

Customization: We can provide following things

1) On request more company profiles (competitors)

2) Data about particular country or region

3) We will incorporate the same with no additional cost (Post conducting feasibility).

Any Requirement Contact us: https://www.forinsightsconsultancy.com/contact-us/

Table of Contents

For TOC Contact us: https://forinsightsconsultancy.com/contact-us/