Automotive 3D Printing Market Size, Trends Analysis Research Report by Component Type (Hardware, Software, Services), by Technology Type (Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), Stereolithography (SLA), Electron Beam Melting (EBM), Selective Laser Melting (SLM) / Direct Metal Laser Sintering (DMLS), Digital Light Processing (DLP), Others), and By Application Type, and By Region Global Market Analysis And Forecast, 2025-2034

Oct-2025 Formats | PDF | Category: Automotive | Delivery: 24 to 72 Hours

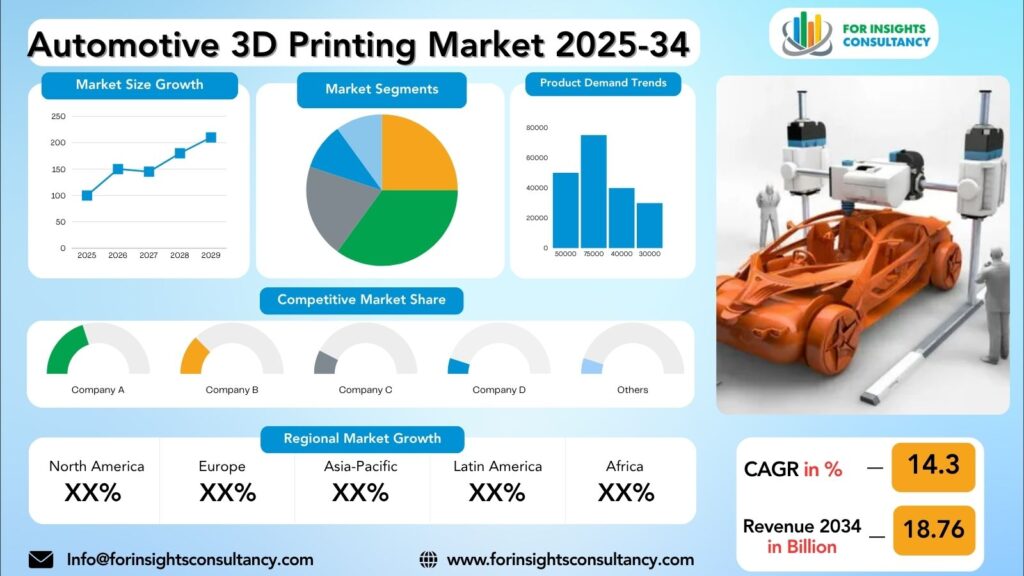

Automotive 3D Printing Market Is Forecast to Increase from USD 5.8 Billion In 2025 To USD 18.76 Billion By 2034, At A CAGR Of 14.3%.

Automotive 3D Printing Market: A Comprehensive Overview and Future Developments

The automotive 3D printing market is undergoing a major change that is reforming the car industry’s supply chain. The market is seeing a rise in demand due to the increasing trend of customization and the demand for lightweight parts.

The rise in material and printing technology innovations are the main factors behind the market growth, allowing for the realization of complex geometries with better time/energy efficiency. The outlook for the automotive 3D printing market is bright, with a wider acceptance along the supply chain and new occurrences of electric vehicles and autonomous driving systems.

Furthermore, companies like HP, Stratasys, and EOS are making investments in R&D for creating advanced 3D printing solutions for the automotive sector. The automotive 3D printing market is going to experience a huge upsurge in the years to come with the incessant technological progress and the gradual shift towards green manufacturing practices.

Market Insights

- In 2024, the Automotive 3D Printing Market is expected to witness significant growth, with the largest regional revenue share coming from North America.

- The market is forecasted to continue growing in this region due to increasing adoption of advanced manufacturing technologies.

- The U.S. population living in urban areas is projected to be around 85% by 2024, indicating a strong market potential in urban centers.

- Additionally, the largest revenue share within the segments of the Automotive 3D Printing Market is expected to come from prototyping and tooling applications, driven by the need for rapid product development and customization in the automotive industry.

- Overall, the market outlook for Automotive 3D Printing in 2024 looks promising, especially in North America.

Market Dynamics

Trends

Increased Adoption of Metal 3D Printing:

The automotive sector is experiencing a massive change as it is going metal 3D printing to fabricate the complex and lightweight parts of the vehicles. As a result, parts made of metals through 3D printing have helped cars to improve their performance and fuel efficiency.

Customization and Personalization:

As a result of 3D printing technology, automotive manufacturers are now able to provide their customers with unique and personalized products that meet their changing demands. By offering various creative design choices, not only are manufacturers getting an edge in the market but also, they are delivering a remarkable experience to their customers.

Sustainable Manufacturing Practices:

3D printing has become a standard solution for the automotive industry, which has been significantly affected by carbon emissions. The adoption of printing has contributed to decreased material waste and energy consumption during production processes, and this is in line with the implementation of clean products and environmental laws.

Supply Chain Optimization:

3D printing technology allows for the production of the required parts in a demand-driven manner and in the immediate vicinity of the consumer. This way, the lead times and storage costs are minimized, and the process of supply chain management for car companies is made simpler and more efficient. Moreover, the availability of the necessary components is better ensured.

Growth Drivers

Technological Advancements: One of the major factors is the continuous technological advancement in 3D printing which includes faster printing, a wider variety of materials, and improved accuracy. This will not only lead to market expansion but also encourage more customers to adapt 3D printing service.

Cost Efficiency:3D printing is an attractive method to lower production costs especially when less or even no traditional tooling is required, and the waste obtained is recycled for utilization. It is anticipated that such an approach will gain high traction within the automotive industry further fuelled by cost savings that the industry will experience

Customization and Personalization: The use of 3D printing is growing as a result of increasing consumer demand for personalized auto parts and accessories. The technology is being applied to develop one-of-a-kind and tailor-made products.

Supply Chain Optimization: Automakers get rid of the traditional stock and manufacturing method 3D printing allows them to move to supply chain flexibility since on-demand production and local manufacturing cut down delivery time and transport cost.

Sustainability: The environmentally friendly nature of 3D printing, with less material usage and lower energy consumption, is in line with the rising trend of sustainability in the automotive industry, and thus is a contributor to market growth.

Restraints

Material Limitations: Although the 3D printing technology has seen exponential growth over time, the basically are still quite narrow of materials, in particular, those which are suitable for automotive applications. In fact, the manufacture of parts which are having desired strength, long life & thermal resistance is almost impossible with current material range.

Cost Constraints: The unreasonably high ‘cost of 3D printing equipment, materials and highly skilled labor force’ can put a cap on the ‘large-scale usage of this technology in the automotive industry’. The monetary value of putting 3D technology to work may be lower than traditional methods; then why even bother?

Regulatory Hurdles: The 3D printing industry cannot untangle itself from slow-moving regulations and standards of the automobile sector. Compliance with safety and quality requirements for the printed parts is nevertheless an arduous, and sometimes complex, procedure.

Scalability Issues: A mass production of automotive parts using 3D printing technology becomes a daunting task of speed, volume, and scalability limitations of the print process. Herein lies a problem of the industry not being able to accept a high-volume production demand as a result of these restrictions.

Intellectual Property Concerns: 3D printing technology that brings about effortless duplication of designs, inevitably invites IP theft and counterfeiting worries in the auto supply chain further than the usual suspects. Intellectual Property rights holders must starve away from the clutches of illegal copies by exercising data security credentials to the max and maintaining confidentiality of product designs.

Opportunities

Increased Adoption: The main reason for the rising use of 3D printing technology in the automotive industry is the application of this technology for the production of prototypes and personalization of products.

Cost Efficiency: 3D printing has made a major jump in its process which has led to the production of complex car parts in a cost-effective way.

Innovation and Design Flexibility: One of the main advantages of 3D printing is the capability of manufactures to come up with very complex and unique designs that can contribute to the overall performance of the car.

Sustainable Manufacturing: The main driver for the use of 3D printing in the automotive industry is the commitment to more sustainable practices which, 3D printing being a method of production with less waste of materials.

Material Advancements: The making of new materials that are compatible with 3D printing with the purpose of enhancing the strength, durability, and the functionality of automotive parts.

Challenges

Material Limitations: The automobile sector necessitates the use of high-quality materials for part fabrication, and a shortage of suitable materials will be a stumbling block for the 3D printing technology application in the whole area.

Cost Efficiency: The prices of the whole process including equipment, materials, and production, are the main reasons why despite all the improvements, 3D printing technology is still not widely used in the automotive industry.

Quality Control: One of the main concerns about the safety and security of the users is making sure that the quality of the 3D printed automotive parts is maintained. Manufacturers face the challenge of taking on high quality control measures in 2024 and 2025.

Regulatory Compliance: The process of computer-aided manufacturing (CAM) to meet the various industry standards and regulations for automotive parts produced by additive manufacturing techniques is difficult and challenging, requiring manufacturers to be always up to date with the latest guidelines.

Automotive 3D Printing Market Top Companies Covered In This Report:

Evaluate The Strategic Positioning And Innovation Pipelines Of Leading Market Companies-From Multinational Enterprises To Disruptive Regional Firms. Understand How Key Players Are Innovating, Expanding, And Capturing Value, And Use Competitive Benchmarks To Plan Your Next Move.

- 3D Systems

- Formlabs

- HP

- Materialise

- Nikon SLM

- Renishaw

- Stratasys

Automotive 3D Printing Market Company News 2024 and 2025

3D Systems

3D Systems is introducing a new, patent-pending module for its large-format EXT 1070 Titan Pellet and EXT 1270 Titan Pellet extrusion printers.

Formlabs

Form 4 and Form 4L 3D Printers: Launched in 2024, the Form 4 is a new flagship resin (SLA) printer with a proprietary Low Force Display™ (LFD) print engine.

Form 4L: Announced in late 2024, the Form 4L is a large-format version with a nearly five times larger build volume, suitable for printing big parts like exterior body panels or large assembly jigs.

Automotive Industry Collaborations & Applications

Company / Supplier Application Key Takeaways

Ford Motor Company

Rapid Prototyping & Manufacturing Aids

To develop the new Ford Explorer EV, Ford employed a variety of 3D printers including the Form 4, Form 3L, and Fuse 1+ 30W. Along with that, they stressed the fastness and the ability of the Form 4 to use different materials as being essential to their rapid prototyping and production of manufacturing aids.

Brose (Tier 1 Supplier)

Tooling, Fixtures, and End-Use Parts

Brose is combining SLA (Form 4L) and SLS (Fuse 1/1+ 30W) technologies to achieve the best results. The Form 4L is mainly for the rapid production of large welding setup parts and fixtures, made possible by the ability to print in a matter of hours, thus enabling the engineers to conduct programming of the welding robots before the metal components arrive. Besides, they rely on SLS for the manufacture of the end-use components such as seat assembly parts.

Vital Auto

High-Fidelity Prototypes & Concept Cars

For the purpose of rapid iterations and the creation of high-fidelity prototypes, the company uses a large fleet of Form 3L and Fuse 1 printers for such OEMs as Volvo, McLaren, and Nissan.

Segmented View of The Industry:

The Automotive 3D Printing Market Is Mapped Through A Multidimensional Lens-Tracking Shifts Across Product Type, Applications, And Geographic Regions. This Segmented Approach Enables Businesses to Localize Their Growth Plans And Align Offerings With The Most Profitable Demand Centres.

Segmentation By Component Type

- Hardware

- Software

- Services

Segmentation ByTechnology Type

- Fused Deposition Modeling (FDM)

- Selective Laser Sintering (SLS)

- Stereolithography (SLA)

- Electron Beam Melting (EBM)

- Selective Laser Melting (SLM) / Direct Metal Laser Sintering (DMLS)

- Digital Light Processing (DLP)

- Others (e.g., Laminated Object Manufacturing, Three-Dimensional Inkjet Printing)

Segmentation By Material Type

- Polymer / Plastic

- Metal

- Ceramic

- Composites and Resins

Segmentation By Application Type

- Prototyping

- Tooling and Fixtures

- Production (or Manufacturing Complex Components)

- Research & Development (R&D) / Innovation

- Spare-Parts / Maintenance, Repair, and Overhaul (MRO)

Global Geographic Coverage:

The Report Provides In-Depth Qualitative And Quantitative Data On The Automotive 3D Printing Market For All Of The Regions And Countries Listed Below:

North America

The North American Automotive 3D Printing Market will see a large growth over the next few years. The market is ready for its extension with such a strong projected GDP growth rate of 2.5% and a low inflation rate of 2%. According to the United States, one of the factors that lead to the use of 3D printing technology is a particular government subsidy designed specifically to support the automotive sector’s innovation. This subsidy grants financial aid to the manufacturers who want to invest in the advanced manufacturing techniques.

The leading procedure for Automotive 3D Printing in North America is the direct sales to the automotive companies. At the same time, the most rapidly developing channel is through the partnerships with the additive manufacturing service providers. In this market, the implementation of sustainability practices is obligatory, and the segment is witnessing a rising trend of ethical sourcing and the preference for local production to lessen the environmental impact of production processes.

Europe

The 3D printing market for automotive in Europe will be expected to have the bigest growth in the next years and this is going to be a result of the positive economic outlook (GDP growth rate of 2.3% and inflation rate of 1.8%). Germany, as the local driver, ranks the government’s investment to push up clean technology, which includes subsidies for sustainable automotive manufacturing processes at the top of the list. This one-of-a-kind program has encouraged the 3D printing trend in the automotive sector in Germany.

In Europe the primary or dominant channel for automotive 3D printing is through collaborations with already existing car manufacturers, while the fastest-growing channel is direct sales to small car companies and aftermarket suppliers. Sustainability and ethical sourcing are variables of a growing importance in the consideration set of consumers in Europe and, therefore, becoming essential factors for success in this market. Localism is also becoming more and more important and the point of focus is on producing automotive parts locally in order to save on transportation costs and cut carbon emission.

Asia Pacific

The Automotive 3D Printing Market in Asia Pacific is likely to experience a steep rise. This growth will be led by the five percent increase in the region’s GDP and a two percent inflation rate. In the case of China, a particular government subsidy encouraging the use of 3D printing technology in the production of automobiles is among the factors propelling the expansion of the market. This subsidy is allowing local automakers to use the money to go into smart manufacturing processes.

In the Asia Pacific, the predominant 3D printing channel is through direct sales to automotive manufacturers, whereas the most dynamic channel is via strategic partnerships with tech providers. The implementation of sustainability practices, which have become mandatory in this market, and the increasing focus on the ethical source of materials and localism as a way to lower the carbon footprint of production processes are evident. Companies in the region are progressively integrating green measures to respond to the requests of consumers for products that are environmentally friendly.

Middle East and Africa

The Automotive 3D Printing Market in the Middle East and Africa is expecting a projected GDP Growth of 3.5%, with an inflation rate of 2.8%. The government’s strategic focus on promoting innovation and technology adoption, particularly in the auto industry, has been identified as the local, non-replicable driver for the product, which is leading to the increased demand for 3D printed automotive parts in the region’s sub-regions.

The most influential channel for automotive 3D printing in the Middle East and Africa is via collaborations with local OEMs, while the trendiest channel is the direct-to-consumer sales through e-commerce platforms. Consumer awareness and regulatory requirements are pushing sustainability and ethical sourcing practices in the region, thus making localism a key trend that is shaping the market dynamics.

Faq – What Global Leaders Are Asking

What is the automotive 3D printing market size and what are its growth prospects?

Automotive 3D Printing Market Is Projected to Reach USD 18.76 Billion by 2034, Growing from USD 5.8 Billion In 2025, At A CAGR Of 14.3% During The Forecast Period. This growth is driven by the electric vehicle (EV) sector, which uses 3D printing to create lightweight and efficient parts, and the increasing industry shift from prototyping to full-scale production.

Who are the key players in the Automotive 3D Printing market?

The Automotive 3D Printing Market Includes Major Companies 3D Systems, Formlabs, HP, Materialise, Nikon SLM, Renishaw, and Stratasys, Others.

What are the main applications of 3D printing in the automotive industry?

The main applications are rapid prototyping for design iteration and production of end-use parts for low-volume, custom, or complex geometries. It is also widely used for tooling, jigs, and fixtures and for on-demand spare parts and maintenance.

What are the main challenges facing the Automotive 3D Printing industry?

The main challenges include slow production speed and scalability for mass manufacturing, coupled with limited material options for high-performance and safety-critical parts. Additionally, the high cost of equipment and materials, along with regulatory and quality consistency issues, are significant hurdles.

What is the future outlook for Automotive 3D Printing Market?

The automotive 3D printing market is expected to see strong growth, driven by the increasing demand for lightweight, customized, and complex components, especially for electric vehicles. This growth will also be fueled by the shift from prototyping and tooling towards serial and mass production of end-use parts.

Valuable Points from Automotive 3D Printing Market Research Report 2025-2034

- Significant changes in Market dynamics.

- Reporting and assessment of recent industry developments.

- A complete background analysis, which includes a valuation of the parental Automotive 3D Printing Market.

- Current, Historical, and projected size of the Automotive 3D Printing Market from the viewpoint of both value and volume.

- Automotive 3D Printing Market segmentation according to Top Regions.

- Automotive 3D Printing Market shares and strategies of key Manufacturers.

- Emerging Specific segments and regions for Automotive 3D Printing Market.

- An objective valuation of the trajectory of the Market.

- Recommendations to Top Companies for reinforcement of their foothold in the market.

Customized Report as per your Business Needs

- Our analysts will work directly with you and understand your needs

- Get data on specified regions or segments, competitor and Vendors

- Data will be formatted and presented as per your requirements

Any Requirement Contact Us: Https://Www.Forinsightsconsultancy.Com/Contact-Us/

Table of Contents

For TOC Contact us: https://forinsightsconsultancy.com/contact-us/